In a nutshell…

CLP/GHS labelling requirements are all about making chemical safety visible at a glance, as mislabelled chemical products can lead to accidents

The Globally Harmonized System (GHS), implemented by the UN is simply the standardized system to achieve that. Similarly, CLP system in the EU is fully aligned with GHS.

Getting this right is not optional, but a legal requirement for anyone placing chemicals on the market.

CHS/CLP rules define how to show hazards using standard pictograms, signal words like Danger or Warning, and consistent safety statements.

Why the label of chemical products is important?

Chemical products are everywhere: from industrial solvents and paints to everyday detergents, cosmetics and cleaners. Behind the label of each product lies a set of standardized rules designed to protect workers, consumers and the environment.

Correct CLP/GHS labeling is more than just a regulatory requirement – it is the frontline of chemical risk communication!

Indeed, the label of a product is the first thing users see before handling a product containing chemicals. A missing hazard pictogram, an outdated H-phrase, or even the wrong signal can create confusion, environmental problems, legal risks for your company or even safety incidents.

What is CLP/GHS labelling?

If you are placing multiple products or mixtures on the EU market or globally, understanding CLP/GHS labelling requirements is essential to maintain compliance, avoid costly recalls, and safeguard your company reputation.

In the European Union, the Classification, Labelling and Packaging (CLP) Regulation is a set of standard rules, in line with the UN Globally Harmonized System (GHS) to correctly label chemical products.

Doesn’t matter if you work under CLP or GHS frameworks, both standardized systems are crucial to ensure that chemical hazards are communicated in a clear and consistent way across countries and markets.

In this post we will explore the 7 key elements of CLP/GHS labelling requirements, the most common mistakes companies make, and how you can ensure that your labels remain compliant and reliable.

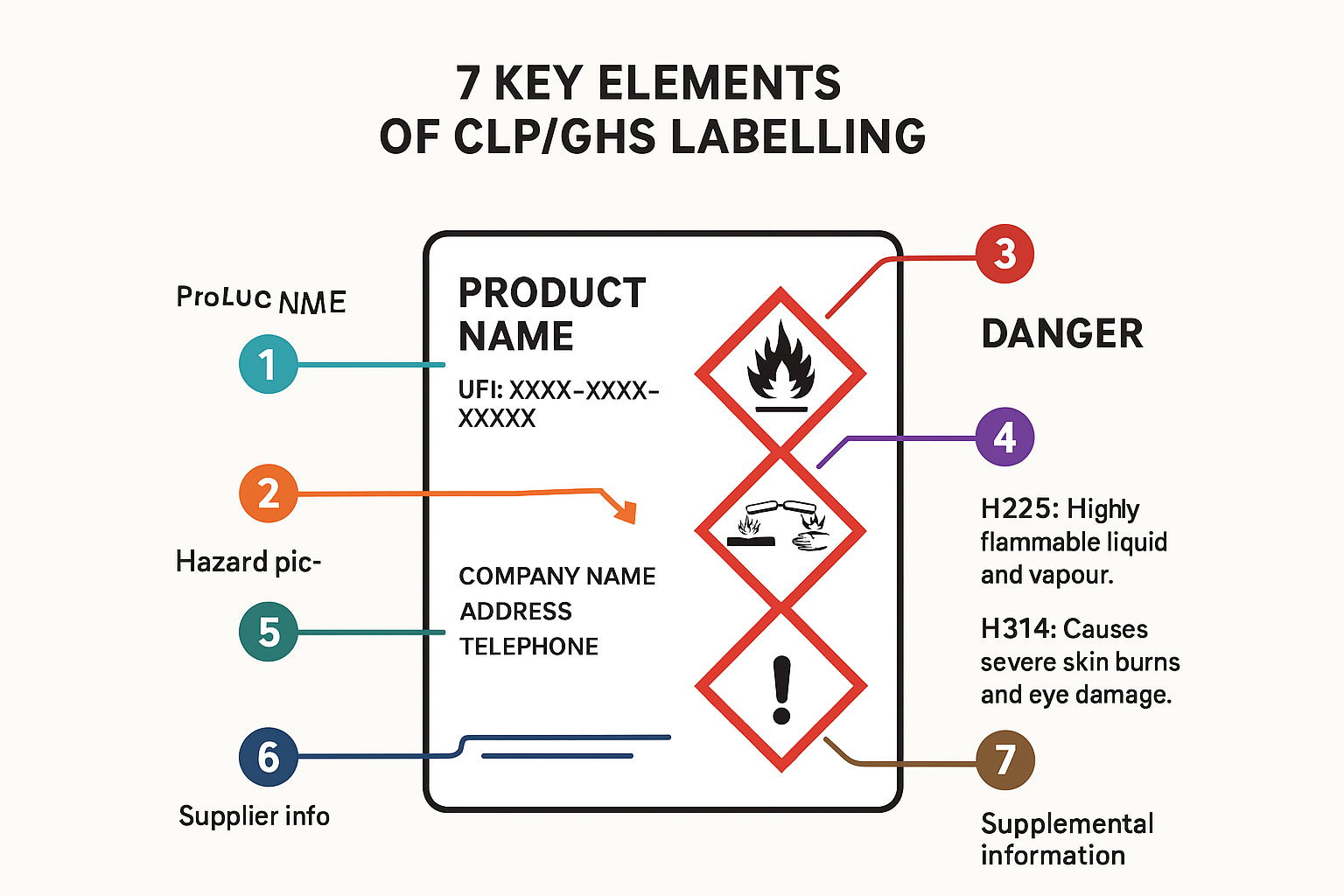

What are the 7 key elements of CLP/GHS labelling?

To prepare a compliant chemical label under the CLP or GHS framework you need to include a set of mandatory elements. Each part serves a specific role in communicating hazards and ensuring the safety of products containing chemicals.

Here’s what you need to get right:

1. Product identifier

Every label must clearly identify the substance or mixture. This usually requires the following information:

- Trade name or commercial name of the product.

- Substance name (if it is a pure substance) or list of hazardous components (for mixtures).

- Unique Formula Identifier (UFI): is a 16-character code that links the label to the exact mixture composition. In fact, from January 2025, a UFI number is mandatory for mixtures placed in the EU market that are subject to Poison Centre Notification (PCN)

All those elements ensure that the label matches the SDS and allows to identify the hazards.

2. GHS Pictograms

The red diamond images, aka GHS standard pictograms, are designed to visually represent chemical hazards.Those pictograms can be found on official sources like EU ECHA or OSHA for the EEUU.

The GHS standard pictograms are a key part of the label as allow users to instantly and visually recognize the chemical hazards.

Depending on classification one or more pictograms should be necessary.

3. Signal words

Two words are used as signal words:

- Danger: for severe hazard.

- Warning: for less severe hazards.

And you must choose only one!

4. Hazard Statements (H-phrases)

The H-phrases are a collection of standardized phrases that provide information about the possible hazards. They are available at GHS or CLP sources in EU official languages.

Each Hazard Statement is linked to a code to make it easily identifiable and translatable to other languages. Nevertheless, the code is not required to be shown on the label.

Anyway, even if you don’t like the phrasing, you are compeled to use H-statements exactly as they appear in the CLP/GHS framework.

Finally, aiming for consistency in chemical hazard communication is the best strategy to implement in your company. You can also check our guide about the 5 Common Mistakes in SDS Authoring (and How to Avoid it).

5. Precautionary Statements (P-phrases)

As its name implies, precautionary statements (P-phrases) are meant to communicate to users the basic precautions that should be taken when handling, storing or disposing hazardous chemicals. They also contain information on how to respond to emergencies.

The advice of an expert is crucial to wisely choose the P-Statements that will appear on yourlabel. Typically, only 3-6 P-statements are selected to avoid overcrowding the label.

Similarly to H-phrases, P-statements are also associated with codes to facilitate discussions; although these codes are typically not required to be shown on the label. They are also available on official GHS and CLP sources.

6. Supplier information

Labels must include the name, full address, and telephone number of the supplier (manufacturer, formulator, importer, or distributor).

This information ensures traceability and lets authorities and users know who is responsible for the product. Indeed, missing or outdated supplier details is a red flag in inspections.

7. Supplemental information

Sometimes, you need to add additional information to your label.

One example are the EUH phrases, specific to the CLP framework and EU markets. Their purpose is to provide information about chemical hazards beyond what it is possible with only H- and P-phrases.

Also, some products require specific product-use scenarios (detergents, biocides, cosmetics, etc.)

Bear in mind that, although supplemental, those additional phrases and information are a mandatory CLP/GHS labelling requirements and not optional.

What are the most common pitfalls when producing labels ?

Even companies or individuals with the best intentions may slip-up when applying the CLP/GHS framework.

Avoiding the following pitfalls will ensure compliance and will build safety and user trust on your brand:

Wrong or Missing Pictograms

Using the incorrect hazard pictogram, or omitting one entirely, can lead to serious compliance issues. The resulting label might be misleading and unsafe and might put your business at risk!

Mixing Old (DSD/DPP) and New Labels (GHS/CLP)

Some products still carry outdated orange square symbols from legacy Dangerous Substances Directive (DSD) or Dangerous Preparations Directive (DPD). Please, keep in mind that those pictograms are no longer valid should not appear on labels.

Language Issues

In multilingual markets like EU, CLP/GHS label requirements impose to be written in the official language(s) of each country were the product is sold.

Do not take the short-cut of producing English only labels! They are non-compliant in many Member States.

Overcrowded or Poorly Designed Labels

The spirit of the law is to provide standardized, clear labels to facilitate chemical hazard communication.

Although it might be tempting, you should avoid adding too much text, placing elements in the wrong order, or using tiny font sizes. All those mistakes makes labels hard to read and increases the risk of errors manipulating hazardous chemicals.

How can ensure that my labels are and stay compliant?

CLP/GHS labelling might seem complex at the first approach, but with the right processes your company can stay on the safe side. Here you will find some good practices:

Use Updated Classification Tools

You should always use updated databases or software to accurately classify your products. Regulations evolve regularly, and hazard classes or cut-off values can change.

Review Official Guidance Regularly

ECHA and OSHA, for the EU and US markets respectively, publish frequent updates, guidance and Q&A documents. Keeping up to date helps you to stay compliant.

Hire an Expert to produce or Verify Your Labels

A regulatory consultant or a compliance officer can check your labels to printing them. This small investment can prevent costly recalls or fines down the road.

Standardize Your Label Workflow

Define who is responsible for SDS authoring, product classification, and label creation. A clear internal workflow will reduce errors and help detect them in a early stage.

Test the Label Readability

Always make sure that your hazard and precautionary statements are legible and understandable to not only regulatory professionals but also non-experts.

Or you can let us guide you thorough the whole process to ensure full compliance in all your projects!

To summarize…

At the end of the day, labels are designed to be readable in a glance. Thus, all the GHS/CLP labelling elements must appear on the label in a way that is:

- Clear: legible font size.

- Durable: resistant to transport and storage conditions.

- Understandable: no contradictions or overlaps.

A well-prepared label is not just regulatory “paperwork” it is the frontline of chemical risk management. Indeed, clear, compliant labels help workers handle chemicals safely and allow businesses to build trust across international markets.

ProTip: At YourChemLab we specialize in CLGP/GHS labelling. If you’d like peace of mind that your labels meet every requirement, we’re here to help!

Contact us today for a label audit or tailored regulatory service

Deja una respuesta